Use caution when agitating manure pits

Exercising caution when empting manure pits may save lives and avoid undue animal death loss.

Agitation of stored liquid manure is a recommended practice extensively followed by farmers. During storage some of the minerals in manure, most notably phosphorous (P2O5), will settle to the lower levels of the stored manure. Agitation suspends the settled minerals and creates a more homogenized crop amendment.

While gaseous emissions are constantly released from stored liquid manure they also, over time, accumulate in the manure itself. The moving and churning of agitation releases these accumulated gases. In barns with under floor manure storage these gases, most notably hydrogen sulfide and methane, pose a significant health risk to both people and animals that are in the facility during agitation.

Farmers recognize the risk associated with manure agitation. But with opportunity for spring manure application just around the corner, it’s important to review all the safety risks associated with removal.

Never enter the barn while

manure is being agitated in the pit below. If you must enter the room, shut

down the agitation unit and prior to entering allow a minimum of thirty minutes

forthe ventilation system to completely remove any lingering gases.

Never enter the barn while

manure is being agitated in the pit below. If you must enter the room, shut

down the agitation unit and prior to entering allow a minimum of thirty minutes

forthe ventilation system to completely remove any lingering gases.

Instruct family members and animal caretakers to stay out of the building while the manure is being pumped and agitated. Young family members and new farm employees may not be aware of the risks associated with manure in deep pits. Don’t assume anything. Prior to pumping manure instruct and remind everyone of the risks associated with manure agitation.

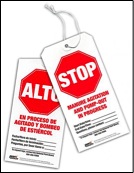

Use lock-out tags to remind everyone of the activity taking place. The National Pork Board provides the tags pictured on the right free of charge to all pork producers. Order yours at the Pork Store.

Set ventilation rate at the maximum level. Adjust fresh air inlets to meet the needs of the barn’s exhaust fans. While it’s never a good practice to chill small animals, minimum ventilation rates may not provide enough fresh air to protect the animals in the barn or room within the barn. If outdoor temperatures and the size of the animals in the barn are such that you are reluctant to turn ventilation rates up, consider delaying manure application or for that application period avoid agitating the manure.

Set the ventilation inlets to meet the needs of the fans but don’t open doors and windows that are not normal fresh air inlets. While opening doors may appear to add more fresh air into the barn, in a large room or barn this unplanned area of incoming air may short circuit the system causing stagnant areas with little or no air movement. Gases may build up in these areas resulting in localized animal death loss.

Be extremely cautious if the manure in the pit is foaming. Foam contains high levels of methane. Agitating the manure will break the foam bubbles leading to methane build up in the building. Across the mid-west, foam and methane have been associated with fires and explosions in hog barns. If there is foam in the pit turn off all pilot lights and all electric power supply, except the electricity required to power the ventilation system, prior to moving any manure.

Never enter any manure pit, small or large, without the proper safety equipment. Hydrogen sulfide is heavier than air and will accumulate in these containment areas. Always assume there are unsafe levels of the gas in all manure pits.

For more information visit

Print

Print Email

Email