Managing bunk silos for maximum forage quality - Ukrainian style

U.S. and Ukraine dairy operations have similar management challenges with forage supplies.

During a recent trip to Ukraine for the 2015 Ukraine Dairy Congress, I had the opportunity to visit two dairy operations near the capitol city of Kyiv. These modern dairy farms were both excellent examples of how the Ukrainian dairy industry in Eastern Europe is becoming more efficient, productive and profitable.

Many of the management strategies made on dairy operations in the United States and other leading dairy nations have been adapted to the more progressive farm operations. However, not all the dairy operations in Ukraine have been able to adapt the larger dairy models. At the conference, three distinct types of operations were referenced.

According to the USDA Foreign Agricultural Service Report, 78 percent of the total raw milk in Ukraine is concentrated in household farms of less than five cows per farm. These represented the “social farms” where a significant portion of milk is consumed within the household, sold to neighbors or in open-air markets in nearby towns. The other types of farms mentioned at the conference were identified as “industrial farms” that would be larger in scale and sell milk to the processors and may have been part of the former collective farm system.

The last type was referenced as a “progressive association farm.” These farms have the advantage of utilizing services such as veterinary, nutrition, farm managers, marketing and commodity buying. The farms visited were considered above average operations and had 17,500- and 21,500-pound herd averages.

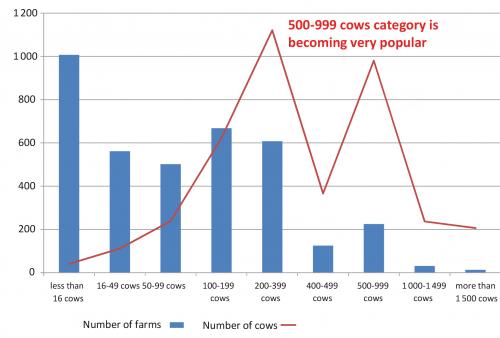

Grouping of Ukrainian commercial milk producers by the number of dairy herd at each farm, 2010, head versus number of farms.

Source: State Statistical Service of Ukraine.

Ukraine bunk silos. On the left, corn silage with moldy top. On the right, notice alfalfa haylage discoloration at the top left of the picture indicating mold and heat damage due to moisture and air infiltration.

Even though the progressive farms have seen improvements in their operations, managing forage supplies is a common challenge. This is not unique to only the Ukrainian dairy industry. In Michigan farms that I have visited, managing the forage supplies at the silo is an area where many producers can often make improvements. These improvements can lead to decreased dry matter losses and make a sizeable impact in reduced economic losses from feed shrink.

Here are a few suggestions to help manage bunk silos more effectively.

- Maintain a safe distance from the silo face. Silage can fall at any time without notice, causing significant injury.

- Harvest at the correct moisture. Harvest haylage at 60-65 percent moisture for bunk silos. Haylage harvested too wet can lead to butyric acid formation, resulting in reduced dry matter intakes for dairy animals. Michigan State University Extension recommends whole plant corn silage to be harvested at 65-70 percent moisture for horizontal silos.

- Pack, pack and pack silos to the recommended density. Recommendations are to have the average density of at least 14 lb/DM/ft3. Uniform silage density throughout the pile, including the sides of the pile, is an essential step in obtaining high quality feed. When you feel you’ve packed enough, pack some more.

- Fill the silo quickly. The silo should have uniform layers of 6 inches for the best results. When filling is done, cover immediately with oxygen-limiting plastic barriers covered with tires that are touching each other.

- Toss off any moldy or caramelized feed and do not feed in TMR.

- Use a silo defacer for maintaining uniform front, ideally removing 12 inches of silage every day.

- Remove silage from top to bottom, not bottom to top. This will reduce air infiltration and mold growth. Additional air can be introduced into the pile when lifting the silage.

For more information, contact MSU Extension educator Phil Kaatz at 810-667-0341 or kaatz@msu.edu.

Print

Print Email

Email